In the defense industry, speed, consistency, and control over production are everything. For Zaffiri Precision, a company known for its high-end aftermarket Glock slides and barrels, bringing barrel production in-house wasn’t just about improving efficiency. It was about ensuring quality. With support from Tsugami America and the right equipment, they found the solution they needed to elevate their operations.

From Outsourced to One-and-Done

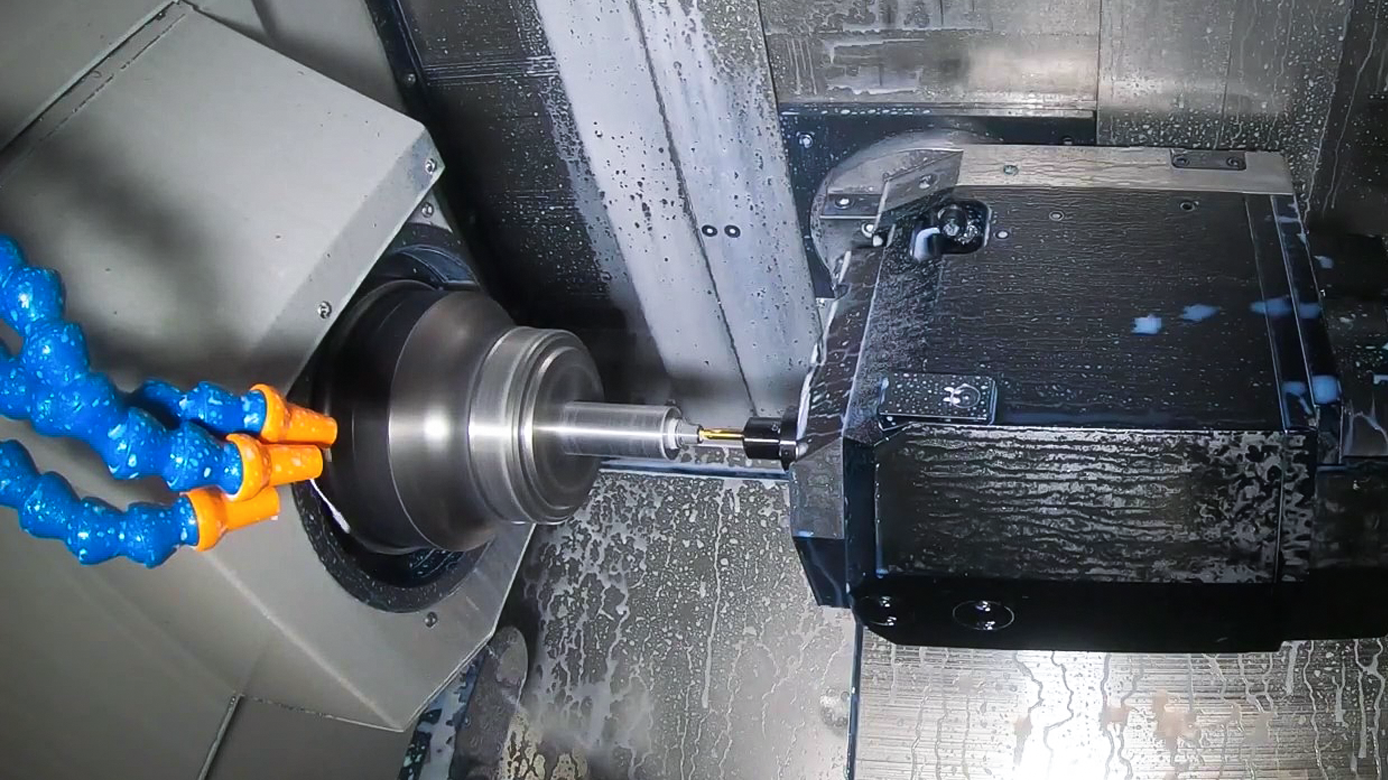

Before making the switch, Zaffiri Precision outsourced their barrels from another manufacturer. But the long-term vision was always to bring that work inside. That vision became reality with the addition of the Tsugami TMA8F, a turn-mill platform that now allows them to complete each barrel in a single setup.

Founder Steven Zaffiri explained how the machine eliminated multiple operations: “We rock the initial part of the barrel on the main spindle, transfer it to the sub spindle, and that’s where we do all the finishing work on the chamber and housing.” What used to take three operations now takes one, without compromising consistency.

Customized for Overnight Productivity

When Zaffiri Precision purchased their Tsugami, they had a clear goal in mind. Working closely with Tsugami America, they developed a conveyor and part unloading system that allowed for unattended production. Paired with a Edge Technologies Rebel bar feeder, the system enables continuous overnight operation.

Today, Zaffiri continues to build on that foundation, working with trusted partners who understand the evolving needs of firearm manufacturers and how to support machines running high-mix, high-volume work. The focus now is on refining and expanding their setup while keeping throughput and quality front and center.

More Than Barrels: Swiss Turning for Small Parts

In addition to the TMA8F, Zaffiri Precision also runs a Tsugami B0325B-II. This Swiss-style lathe is their go-to for small parts — including thread protectors, guide rods, trigger pins, and washers. They’re able to produce complete assemblies with efficiency and repeatability, often machining multiple components from stainless material that offers greater durability than plastic alternatives.

Proven Performance and a Clear Path Forward

Zaffiri Precision made the move to bring critical parts in-house, and the decision continues to pay off. “With this machine, we’re able to do that effectively, rapidly, and consistently,” Steven said of the B0325B-II. And when machines need attention, he noted, they’ve been able to get the parts they need quickly to minimize downtime.

As the company grows, they continue to strengthen their equipment lineup and lean into partnerships that support their evolving production goals. With Tsugami technology at the core and added support from teams now working alongside them, Zaffiri Precision is building a solid foundation for scalable, reliable manufacturing in the firearms space.

See Zaffiri Precision's Story In-Action

Take a look inside Zaffiri Precision’s shop and see how they’re putting their Tsugami machines to work. The video walks through their process, from barrel production to small parts, and shows how everything runs day to day.

Looking to take your own production to the next level?

Click Here to explore Tsugami solutions, automation options, and the support behind it all!

Works Cited

“About Zaffiri Precision.” Zaffiri Precision. https://zaffiriprecision.com/about/

“Precision360.” Precision360. https://precision360.com/

“Tsugami America.” Tsugami America. https://www.tsugamiamerica.com/